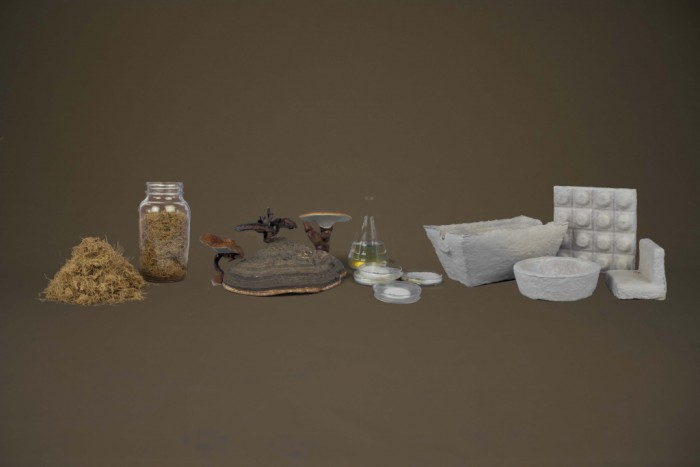

It comes as no surprise that plastic packaging contributes massively to pollution - ending up in landfills unable to biodegrade, or in oceans harming marine life. Radial was chosen as one of What Design Can Do’s 16 No Waste Challenge Winners thanks to a crafty solution to mitigate some of the harmful pollution caused by synthetic materials. They achieve this through a biofabrication process using agricultural waste to produce carbon neutral materials that are suitable replacements for styrofoam, MDF and animal or plastic leather.

The company uses the natural metabolic properties of fungi to transform local agricultural waste into malleable materials. “While the fungus grows it is able to bind the agricultural fibres, working as a natural glue, allowing the development of plastic-free materials that at the end of their useful life are completely biodegradable,” says Mexican founder Ricardo Muttio Limas.

Limas had sustainable solutions in mind from the onset of his entrepreneurial journey, but it was a long-winded process of trial and error. “After experiments with composters, cultivation beds, and orchards, among others, we developed home-made edible mushroom farms, and that’s where we learned about the possibility of growing materials from fungi and we decide to focus on this tech,” Limas explains.

While Radial is a step in the right direction, there are still a lot of misconceptions about natural materials and textiles, especially with many consumers focusing on aesthetics over sustainability. “The industries have made consumers believe that the only way to obtain functional materials is from petroleum derivatives,” states Lima.

“In addition, this has created an idea that to have functional products, the perfect aesthetic appearance is needed in terms of colour and texture. To adopt new sustainable materials, as consumers we must learn to value products that could be different in appearance, but despite this, these materials will fulfil their function during their useful life and be totally sustainable.”

Lima hopes that large brands will adopt sustainable material production practices and be transparent in their flow of information to consumers so they can make the right purchasing decisions. He believes that in order to really make a sustainable impact, big brands need to “start using low environmental impact materials.”

Leading by example, Radial has big plans to evolve into a large-scale biofabrication platform to offer sustainable solutions to large industries, starting in Mexico and expanding into Latin America before eventually going global. Building these industry partnerships could be revolutionary for climate progress.

“Radial represents a circular economy bridge between two of the most important industrial sectors in Mexico, agriculture and manufacturing, able to transform waste from the agricultural industries into sustainable materials for the manufacturing ones, thus reducing environmental pollution due to mismanagement of waste and reducing the use of toxic materials,” Lima says.

We look forward to witnessing the escalation of Radial’s positive impact on the world!

See More:

No Waste Challenge winner, Clothing Loop swaps Fast Fashion for sustainability.

From pineapple waste to period products.

No Waste Challenge winner CarbonCraft is transforming construction.

Sixteen global waste-busters awarded top honours by What Design Can Do.