From the Series

Twenty years ago it was almost unthinkable that cellphones would become as ubiquitous as they are today. “But what will I do with a cellphone?” was a question that many were asking, unable to imagine that in the future we would have difficulty living without this handy piece of mobile technology.

Today we could ask the same question about 3D printing. Could it, in a couple years’ time, become everyday tech? Or bigger still, could it lead to something groundbreaking? The third industrial/manufacturing revolution, if you will?

Michaella Janse van Vuuren is excited about the possibilities of 3D printing. She’s an artist with a PhD in electrical engineering, who is at the forefront of 3D printing in South Africa.

“There’s lots happening in the industry, she starts, “this is the future of manufacturing.” To prove this Janse van Vuuren recently curated and presented Agents of the 3D Revolution in Johannesburg, an exhibition and lecture series that brought some of the world’s foremost 3D makers and thinkers to Johannesburg.

The exhibition, which took place at the FADA Gallery at the University of Johannesburg last month, presented a dynamic mix of 3D printed sculptural design, as well as the machinery and technology used to create these designs. A series of seminars also formed part of the Agents project, whereby participants and visitors were exposed to 3D design and print experts from around the world.

Though the exhibition was the first of its kind in South Africa, research into 3D printing has been happening for a long time. Janse van Vuuren cites Professor Deon de Beer as one of the key figures in this industry. As the executive director of Technology Transfer and Innovation at Vaal University of Technology, De Beer has been pioneering a way forward for 3D printing in South Africa.

“South Africa is potentially at the forefront of 3D printing but a lot still needs to happen to cement this position,” Janse van Vuuren explains. Government and universities need to get more involved and people generally need to be better informed about the myriad possibilities and benefits of this technology, Janse van Vuuren believes.

In its simplest form 3D printing is a new way of making stuff. 3D printing – also known as “additive manufacturing” – is the process whereby a physical shape is made from a digital model. Nearly any shape or form can be made with the additive process whereby successive layers of a specific material are layered on top of each other to build up the desired product.

Not only does 3D printing reduce, or eliminate, the shipping costs of manufactured goods, it also makes it possible for more people with ideas to have businesses because access to markets is no longer one of the biggest concerns in the manufacturing process. “It could mean the decentralisation of manufacturing, almost as if people could become part of a new global economy,” Janse van Vuuren muses. As an example, the Robohand project by South African carpenter Richard van As illustrates the power of 3D printing, allowing people to change their world for the better. Robohand is the 3D printed hand Van As designed and printed for himself following an accident in which he lost his hand. This project would not have be possible without the advantages of digital manufacturing.

Other benefits of 3D printing include material options and customising possibilities. Though materials like nylon, ABS plastic, bronze, silver, wax and titanium are most widely used, there is almost no limit to the kinds of materials that will be employed in 3D printing, Janse van Vuuren says. “It’s just about investigating and understanding the possibilities and properties of different materials.” In terms of customisation 3D printing holds a number of benefits for the dental and medical industries. In the past six years alone about fifty million unique laser-sintered dental crowns, copings and bridges have been created.

3D printing is already quite widespread in jewellery design, medical implants and in the automotive industry. Aerospace giant Boeing, for example, is already flying with titanium 3D printed parts while NASA 3D prints an injector. Manufactured with traditional processes it would take more than a year to make but with these new processes it can be produced in less than four months, with a 70 percent reduction in cost, Janse van Vuuren explains. Similarly, doctors have placed about 30 000 hip implants, made by Arcam's 3D technology.

While the possibilities seem endless Janse van Vuuren points out though that there are still a number of key issues around 3D printing that need to be researched, and then regulated somehow. Safety standards, legal issues and copyright are just some of the concerns that will become more pertinent as the 3D printing becomes more popular and accessible.

While there is much work to still be done to make 3D printing more both more accessible and more popular, Janse van Vuuren says it is already fairly accessible to the layman. A place like idea2product Lab or software like AutoDesk123d is a great way to start learning about and experimenting with small-scale 3D printing. Online 3D print bureaus like i.Materialise, Kraftwurx, Ponoko, Shapeways and Sculpteo lets you upload your 3D file and order the design 3D printed in your choice of material.

But, even as it becomes more accessible there are some basic skills that one would have to master to get the full benefit out of 3D printing projects. “Designers for example, or people already working with the design of a product, will have a bit of an advantage because they probably already understand things like material possibilities and product dimensions,” Janse van Vuuren says.

3D printing is about learning and understanding how things are made. For this reason Janse van Vuuren believes that 3D printing should also be positioned in a craft setup where the emphasis is on the making part, as opposed to a lab setup were the focus tends to be on processes – the former being more about art and the latter about science. “In South Africa too much of a distinction is still drawn between art and science but in 3D printing they come together very nicely.”

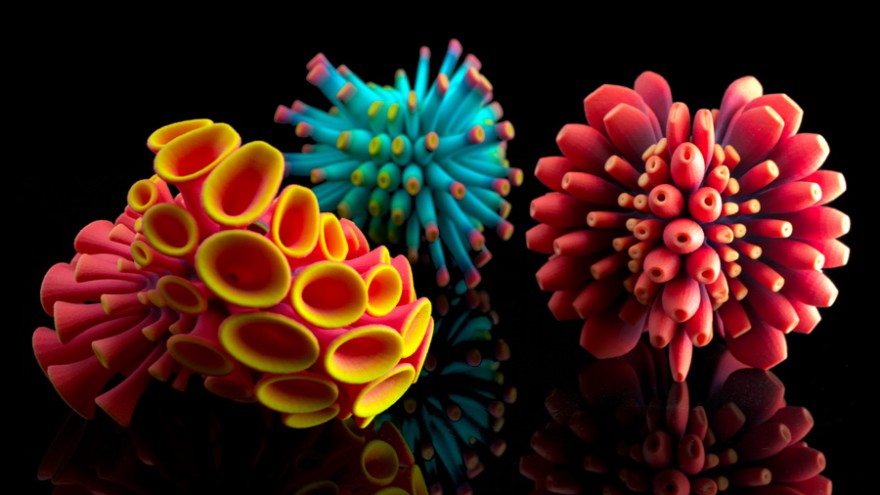

Janse van Vuuren’s own work exists at the intersection of art and science. As a digital artist she is ahead of the pack, the difference with her work being that she uses moveable parts that add a lot of complexity to the printing process. “It then become about dealing with more than just the object, but also with the space between the object. Each component then needs to be considered down to the last detail,” she explains.

From September 2013 to August 2014 Janse van Vuuren’s work will be featured in the London Science Museum. Her work will also be featured in the 3D Printshow in London, Paris and New York. Among a host of other nominations and international recognitions, she was named “the most interesting new talent to watch” at Design Days Dubai 2012 by Rabih Hage, a respected gallerist pioneering the growth of design-art.

For Janse van Vuuren 3D printing represents a break from the traditional ways of disseminating art, while allowing art to pioneer a path that manufacturing has not yet come to realise.