From the Series

Inspired by load-shedding (power-cuts), South African Royal College of Art (RCA) graduate Charlotte Slingsby has designed a new alternative energy solution: Moya. It is a lightweight, flexible sheeting material, which can adapt to a diverse range of surfaces and spaces and independently harvest low-grade wind energy.

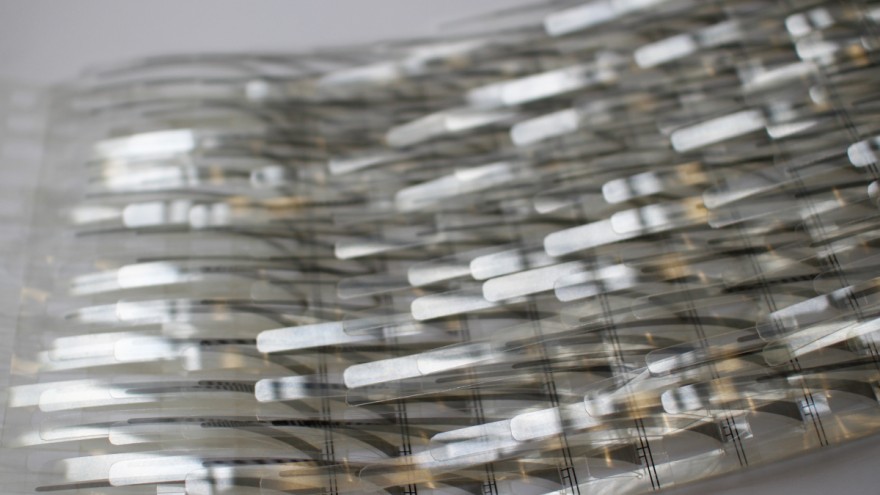

Where wind energy generated by turbines requires durable, advanced and costly infrastructure as well as high-speed winds, Moya seeks to generate energy without using prime real estate and expensive infrastructure. Each sheet contains thousands of freestanding filaments that are each embedded with flexible piezoelectric film.

Piezoelectricity is electricity resulting from pressure and in Slingsby’s design as the wind moves each filament on a sheet; the strain energy caused by the movement is converted into electrical energy. The piezoelectric material is laminated and die-cut in large overlapping and interlocking sheets to create the filaments. Combining the sheets enables variation in the density of filaments for different wind conditions, while still employing the same base structure.

“A central factor informing the functional design of the filaments and the sheet was achieving easy and affordable mass-production,” says Slingsby.

A functional designed was reached by creating the optimal compromise between Moya’s capacity for energy generation and creating a simplified design that is efficient to mass-produce, install and maintain.

We spoke to Slingsby about Moya, her wind energy design for the future.

What were you doing before RCA? What was your experience there like? Any valuable lessons you've brought home to South Africa?

I completed my honours degree in electromechanical engineering at the University of Cape Town, which gave me a solid foundation in engineering. I am passionate about art and design; therefore, I decided to pursue specialising in a field that integrated both design and technology. The double masters in engineering and art offered by Imperial College London and the Royal College of Art presented an incredible opportunity for me to combine my skills and passions in an effort to develop a product that could contribute to development in South Africa

The experience was intense and exciting. I had the privilege of working among brilliant talent while having access to extensive resources in terms of material, machines and knowledge. This allowed me to experiment and learn non-stop!

What was the testing phase like? Can you light anything up; say a lamp using the energy Moya generates?

The prototypes were developed and tested in a wind tunnel. A prototype of the flexible sheet was produced with all the elements embedded in a single sheet. LED’s were integrated into the flexible sheet as a means of directly transferring the energy to an immediate application. The energy is first harvested and rectified, then stored intermittently in capacitors

How far along are you in making the project a reality?

I am currently in the research and development phase. I am in the process of sourcing funding with the goal of bringing Moya power to mass manufacturing level. I have made some exciting contacts and hope to see this project through to implementation.

Is the project scalable? Can we expect to have a few Moya panels in our homes anytime soon?

This is my hope and aim.