The African Dung Beetle is an interesting little creature. Known as rollers, they feed on faecal matter, rolling it into round balls for easy transportation and transforming it into food or material for shelter. With an internal mechanism allowing it to roll around and mimic the movements and utility of the beetle, as well as a specially developed reactor that controls its gasification function, the Dung Beetle Project takes its lead from the insect, cleaning up waste and transforming it into something useful.

A collaborative project between non-profit organisation Alliance Earth, South African inventor Pierre “Pops” Pretorius, and American artist Nathan Honey, the Dung Beetle Project is a moving, educational sculpture that turns single-use plastic items into usable fuel.

The issue of single-use plastic is a global one. Despite stricter regulations, the plastics industry continues to see an increase in production. The accumulation of these products ultimately afflict our land, waterways and oceans, harming us in a variety of ways. The Dung Beetle Project hopes to educate people on the effects of plastic pollution and lend value to this waste.

“We want to change people’s perceptions around what plastic is,” the project’s finance and marketing director, David Terblanche told Inhabitat. “Right now it’s viewed as a waste, as litter, as a blot on the landscape,” but the Dung Beetle Project could enable communities to see “this is a commodity that we can harvest, that it’s got some value, that we can turn it into something.”

The system employed by the Dung Beetle Project was developed by Pretorius, an inventor who lives in the rural Limpopo Province of South Africa. For years, he had been experimenting with macadamia nut shells in the generation of a gasification system – a method of pyrolysis – that could produce various forms of fuel. Troubled by the amounts of discarded plastic that he noticed accumulating across the country, he began to consider whether this waste could be employed in a similar way.

What Pretorius discovered was that nearly any kind of plastic could be gasified. Using a single cycle system, shredded plastic is first placed inside an oxygen-free reactor. From this, gases rise up and physical particles are recirculated to be burned again. After running through cooling ribs, the gases are condensed into a liquid state. The system is able to produce low-emission diesel, as well as petrol and syngas, while no harmful smoke is able to escape.

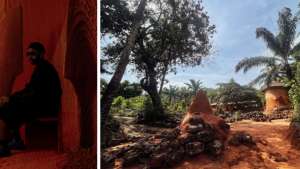

Built by Pretorius, Alliance Earth director Jeffrey Barbee and a crew of 25 people from all across the world, the Dung Beetle structure is made almost entirely from recycled metal. Created using African skills and technology, it features an enormous, three dimensional figure of a beetle, a compartment housing the reactor system, and an art stage that unfolds from the heavy duty trailer as a teaching and learning centre.

Throughout its construction, the team was also careful to utilise widely available scrap materials in an effort to ensure that the system could be emulated by those with limited resources. All of the building plans were made open-source and available to all. The team behind the project plan to have it travel around South Africa to educate rural communities on how they can create their own gasification units.

“We want to spread the message,” Terblanche adds, “and if we can get hundreds of these out there, then we’re going to have hundreds of communities who are cleaning up their own plastic. And then at a community level, you start changing people’s behaviour so the plastic doesn’t reach the ocean.”

Keep up to date with the movements of the Dung Beetle Project here.

Read more on innovation that is helping to save our environment.

Beijing’s Smog Free Tower turns polluted air into jewellery