From the Series

First Published in

Water, soil and manpower. All you need to make a mud brick. Add to that the cost effectiveness and energy efficiency of mud brick buildings, and one has to wonder why more architects, designers and builders are not using mud brick as a way to build better houses.

Meet Malcolm Worby. A British-born architect who was building with mud brick long before the greenies took notice of it or changing weather patterns necessitated it. Worby was working in the United States in the late 1970s when the worldwide oil crisis prompted the US government to give individuals solar tax credits for homes built with energy efficiency as a priority. Coupled with the property boom of the time, Worby found himself building countless mud brick mansions and villas, and gaining valuable experience.

Bored with building “big silly houses for big silly people”, Worby came to South Africa in the early 1990s. “There was an open-mindedness here that I liked and I thought that my experience would fit in well with that.” He was keen to use his experience to help people in some way and found that SA was the perfect place to do that.

Worby works as a consultant on projects in rural communities, most notably HAPPI, the Homeless and Poor People’s Initiative, which teaches people to build using mud bricks, empowering them with a sense of home ownership. In addition to addressing issues around housing, he also develops skills such as construction, bricklaying, planning and home maintenance among people in rural communities. Bodies like the United Nations and other large interest groups often initiate the projects.

When he is not out in the field re-teaching a young generation how to employ an age-old building technique, Worby is fighting with government and various policy-makers to recognise mud brick building as an efficient and legitimate way of building. “The government has an idea that poor people must have the same dwellings as rich people. But cement houses rely on insulating materials for comfort, which poor people can’t afford to add to their cement blocks because it’s simply too expensive... When it’s finished these ‘houses’ are little more than shelters, certainly not comfortable homes.”

Worby is adamant that South African RDP houses should be built with mud bricks. He explains that mud brick houses are the ultimate low-cost energy efficient housing solution. This is why more people across the world live in mud brick houses than all other mediums combined. Mud brick houses are found throughout Africa, in the Middle East, across the Americas, and also in China and Japan. “It’s just a good way of building,” Worby says. “The materials to build with are not only easily available but their thermal massing keeps houses cool in summer and warm in winter.”

The reason mud brick building is not more widespread in South Africa is complex and multi-layered. A lack of vision, good leadership, management and other bureaucratic hassles do not recognise mud bricks as a legitimate building form, stoking the (local) perception that mud brick houses are inferior to cement dwellings.

Worby tells of a recent project for the United Nations in northern Limpopo where a group of local women cornered him and interrogated him about “why a white man is telling them to build houses and why the white man is not teaching them to build with cement block”. He has developed a candid “show-and-tell” type response to these concerns. “These people all have both mud brick and cement houses in their villages. So I ask them where they like to be when it’s really hot. They unanimously answer in the rondawel because it’s cooler than the cement house. I ask the same about winter [with the same answer]. Then I explain that they have been right all along, it’s the white man that’s been wrong all along.”

In Worby’s experience women are especially keen to learn about mud brick building. The women are faster to realise that mud brick building is better and more affordable while the men tend to be discouraged by the stigma of it being the destiny of the poor. Worby likes to show people pictures of a rondawel built of mud brick and pictures of a wealthy person’s mansion built out of mud brick to illustrate the superiority of the material. “The people then ask me why the rich people can’t afford to build a house out of cement,” Worby laughs.

Many of the older people in the communities Worby works with have built with mud brick before but they lack knowledge of basic construction principles. “They tend to just put the mud brick on the ground. When it rains they have problems with damp. We teach them to build proper foundations using rock from the area if it is available.” Worby finds that most areas have enough rock to build a foundation for a house of between 40 and 45 square metres. A house of this size typically uses between five and seven bags of cement to complete. A range of other extra materials and additives, like lime, can be added to a mud brick building but it’s not necessary.

Worby tries as much as possible to use materials and artisans that are available on the site. He finds that most locations in the country have some suitable soil and willing hands. When he is hired by an NGO or company to build mud brick houses in a community, he typically goes into a village and enquires of the head of the village about the local builders. Each village usually has a builder with which Worby then works closely and teaches various skills that are in turn taught to the community. “In this way it becomes a community-based building company and I just give them guidelines and advice to ensure that the building meets various standards,” Worby says. It is also the best way of ensuring that the payment and pride stays in the community.

Despite the obvious and demonstrated benefits of building with mud brick Worby feels a lot of frustration at government and local authorities’ refusal to discuss and learn about the advantages of the material and technique. “I do a lot of presentations to government urging them to take note of mud brick building but they don’t actually do anything about it. But I reckon if it happens independently at grassroots level, like it does, they will eventually take notice,” he says.

The foundation has been laid, now it’s up to government and stakeholders to realise the quality of life and monetary benefits of mud brick building. At least funding is not an issue, Worby happily reports. “The white western conscience like to throw money at development problems and we’re not complaining.”

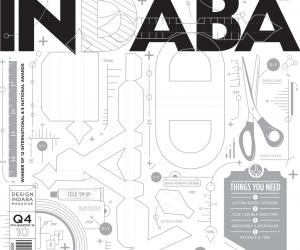

Make your own mud brick

Step 1

Create a structured form. Wood works well as a material. Shape the form to the size that you would like the mud brick to be. Worby likes to build a form that can make two mud bricks but is still suitable for a single person to manage.

Step 2

Mix soil (ensure that soil has a clay content of 20% or more) and water into a porridge-like texture. Add extra soil or water as the texture requires. A very watery texture could mean that the clay content is not exactly right. Remedy this by adding a bit of lime.

Step 3

When the texture feels right, pour the mixture into the brick form created in Step 1.

Step 4

Leave the bricks to dry in the sun. The time needed to dry will depend on the heat of the sun, and thus the season.

Step 5

Once the bricks are dry they are used to build in exactly the same way a cement brick is used. The same soil and water mixture is used for the dugga (mortar). It will be good for the next 100 years, Worby guarantees.