Scientists at the University of California San Diego have developed an ink that can repair itself if torn or damaged. It is part of an effort to make delicate devices and sensitive electrical circuits more durable. This material could make batteries, microchips and wearable textile-based electronics totally self-healing.

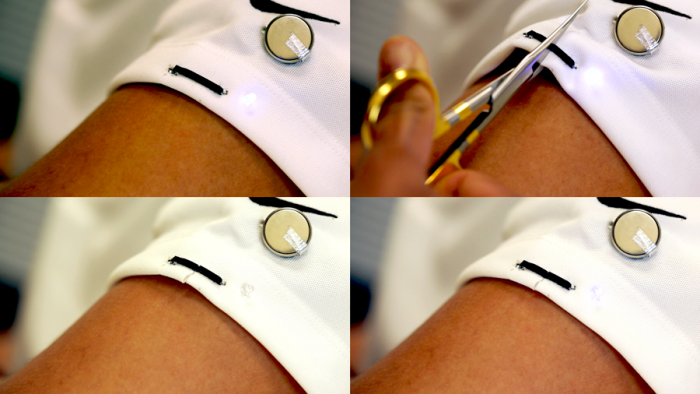

The crucial ingredient of this innovation is magnetism. Engineers use microparticles that arrange and reconfigure themselves according to a strong magnetic field. As shown in the video below, if a line of the solid ink is cut in half, the particles are drawn back together and the electrical connection is remade.

A device or circuit that is printed with this material could restore itself without the need for human intervention. But there is a limit to the power of magnetism in such small scale.

Cuts or breaks of up to 3-millimeters are restored with relative ease but damage larger than that would need stronger magnetism. The speed at which the magnetic ink merges itself still constitutes a new record in the field of self-restoring electronics.

Joseph Wang, chair of the nanoengineering department at UC San Diego said, “Our work holds considerable promise for widespread practical applications for long-lasting printed electronic devices.”

Current self-healing materials typically require a trigger to set the restoration in motion, but the UC San Diego team’s solid ink gets to work immediately after sustaining damage, healing itself without the need for a catalyst.

To test the theory, scientists applied the ink to a host of computer circuits, batteries and textiles before damaging them repeatedly. The circuits were cut and torn multiple times and the magnetic ink reformed after each instance (while losing a tiny bit of conductivity along the way).

Amay Bandodkar, a postdoctoral researcher at Northwestern University and one of Wang’s colleagues emphasised that the new material was made with basic ingredients that most manufacturers should have access to: “We wanted to develop a smart system with impressive self-healing abilities with easy-to-find, inexpensive materials.”