In its two-dimensional form, graphene is thought to be the strongest of all known materials. Translating that two-dimensional strength into useful three-dimensional materials has not been possible, until now. By compressing and fusing flakes of graphene, researchers at MIT have designed a strong yet lightweight material that is ten times stronger than steel and has a density of just five per cent.

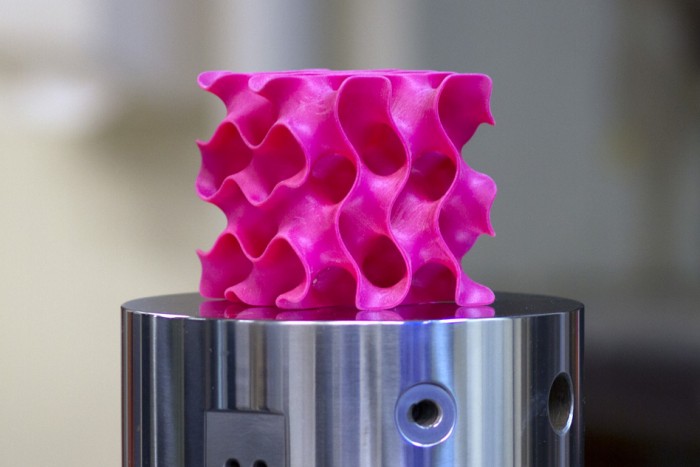

The research findings indicate that the crucial aspect of the new 3-D forms has more to do with their unusual geometrical configuration than with the material itself. This means that similar strong and lightweight materials could be made from a variety of materials by creating similar geometric features. The unusual geometric shapes that graphene naturally forms under heat, known as gyroids, are so complex that “actually making them using conventional manufacturing methods is probably impossible,” says Markus Buehler, head of MIT’s Department of Civil and Environmental Engineering.

Using a combination of heat and pressure, the team was able to compress small flakes of graphene, producing a strong, stable structure. They produced a variety of 3-D structures and subjected them to various tests.

Previous research had suggested that it would be possible to create 3D graphene structures so lightweight that they would be lighter than air and could be used as a durable replacement for helium balloons. However, this new research at MIT rules this possibility out. The current results indicate that at such low densities, the material would not have sufficient strength and would collapse from the surrounding air pressure.

Other possible applications of the material that require a combination of extreme strength and light weight could eventually be feasible. “You can replace the material with anything. The geometry is the dominant factor,” explains Buehler.

For example, a concrete structure such as a bridge could be made with this porous geometry, providing comparable strength with a fraction of the weight. Or the application can be used in a filtration system for either water or chemical processing.