As development in 3D printing continues to grow, so does concern over the sustainability of printed products. While some printing studios are finding substitute printing materials, the majority are still using plastic or non-recyclables. 3Dom is an American company dedicated to creating sustainable, biocomposite and eco-friendly alternatives to the standard synthetic plastic materials.

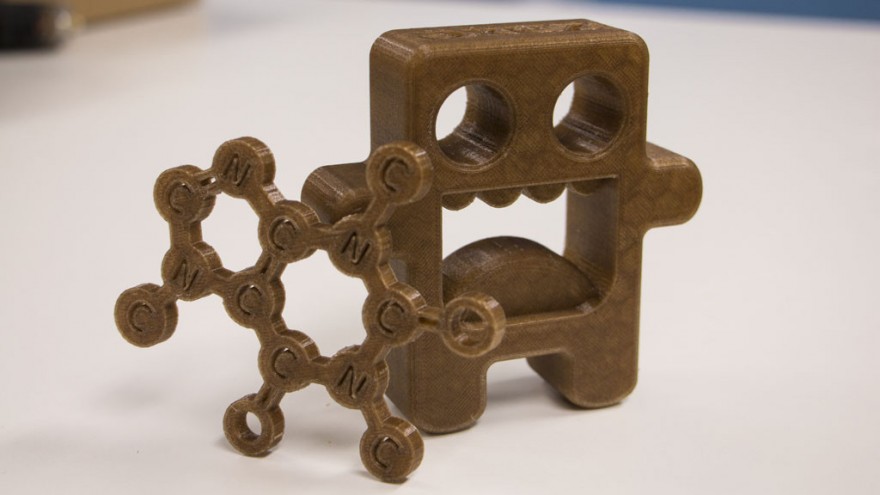

Its latest product, Wound Up is a new 3D printing material made from discarded coffee pulp waste. In the UK alone, over 500 000 tonnes of coffee pulp is produced every year, and on a global scale this amounts to millions of tonnes of coffee by-product that goes to waste.

The bio-based material, which was produced in collaboration with biocomposite specialists c2renew, combines the coffee grounds with a biodegradable thermoplastic called Ingeo PLA – a plant-based polymer, which produces 75 per cent less greenhouse gases than traditional polymers.

Wound Up comes in a thread-like form and is packaged with 3Dom’s trademarked Eco-Spool, which is entirely made from 100% bio-based materials, and is carefully wrapped to avoid tangling and printer jamming.