The world of manufacturing has come a long way from the mechanisation of the textile industry in the 18th century to the mass production of the 20th century. Currently manufacturing is increasingly becoming digital, heralding the third industrial revolution. Carlo Ratti's digitally fabricated and programmable furniture are a case in point.

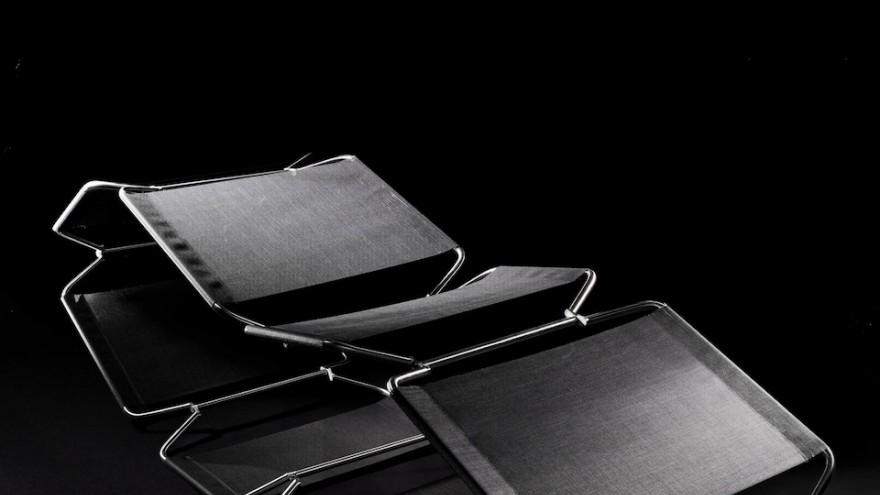

Ratti, director of the MIT Senseable City Lab and partner at Carlo Ratti Associati has collaborated with Cassina, Italian high-end furniture manufacturer, to create two digitally fabricated prototypes that explore the idea of a mutating domestic environment.

There have been many explorations into digital fabrication, from 3D printing to laser cutting, in the world of furniture prototyping and even small ranges in recent years. Here for the first time, we see digital fabrication entering the mainstream production process, says Ratti.

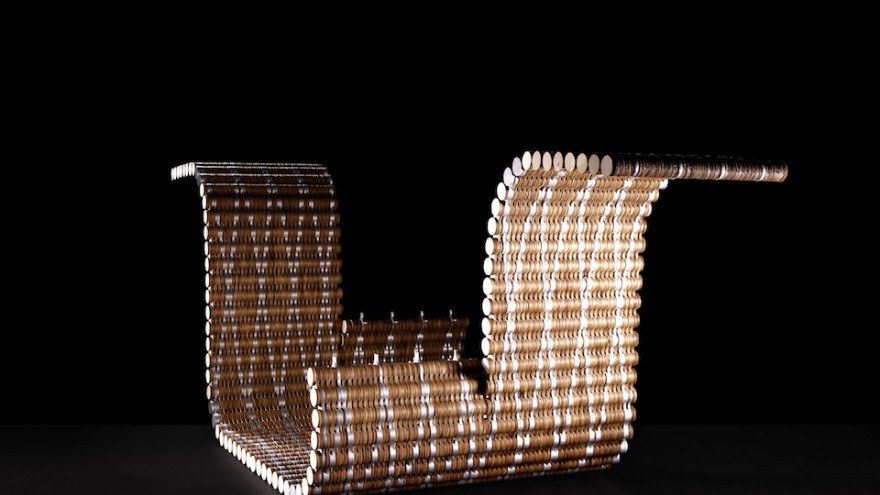

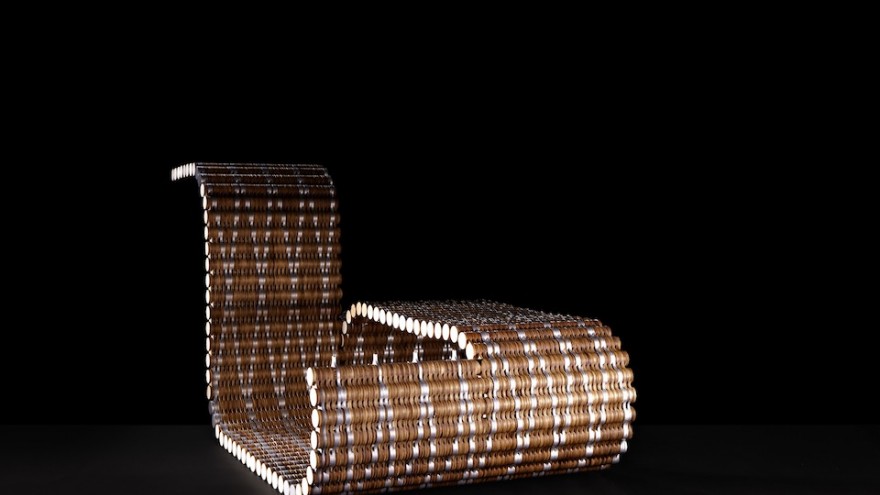

With the changing needs of the user, the furniture pieces are flexible and allow a number of different configurations. A system of hinges, each one different to the next, was digitally fabricated to form chains that created a module. Because the hinges were individually designed to rotate at different angles, you can physically manipulate the function of the module for different uses.

The adaptable MyWing table can be reconfigured to be a work space or coffee table.

The same principles were used to design and produce the ChainSofa, a transformable piece of furniture that can either be used as a chaise lounge, sofa or bed.

Both pieces will be on display as part of the Erasmus Effect: Italian Architects Abroad exhibition that focuses on Italian designers working internationally, held at MAXXI, the National Museum of the XXI Century Arts in Rome until 6 April 2014.