The pineapple has enjoyed its moment in the sun as a popular décor motif on everything from tea towels and t-shirts to cell phone covers and lamps.

But the Ananas Anam team, founded by Royal College of Art graduate Carmen Hijosa, has found a way to make pineapples into something more than a popular print subject and cocktail ingredient: they’ve developed a textile from it.

The textile, Piñatex, is a leather-like textile taken from the fibres of the pineapple leaf which is typically discarded after the fruit is harvested.

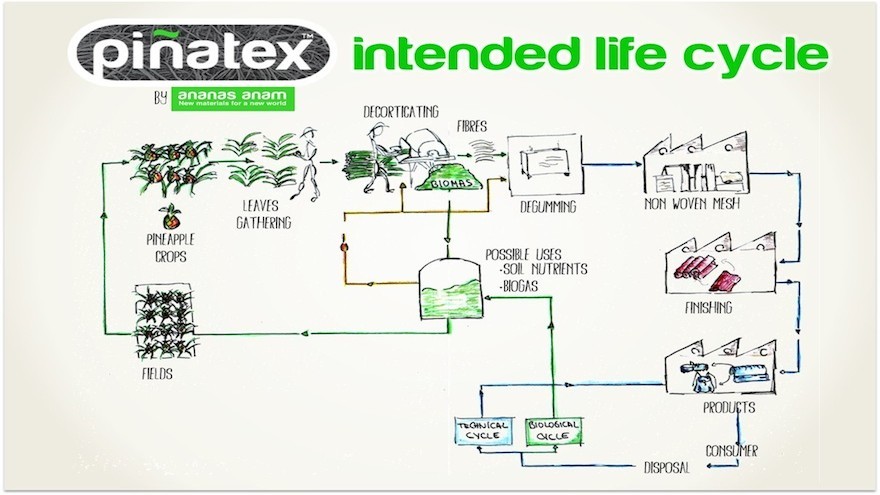

The fibres are extracted from the leaves in a process called “decortication”, which is the removal of the membrane or fibrous cover of the pineapple waste. This is done on the plantation by the farming community.

The by-product of decortication is a biological material or biomass taken from living, or recently living, plant-based organisms.

The fibres then undergo an industrial process to become a non-woven textile which is the base of Piñatex. The material, which can be used as a leather alternative, is a breathable, pliable and easily-dyed textile suitable for use in the fashion, accessory and upholstery markets.

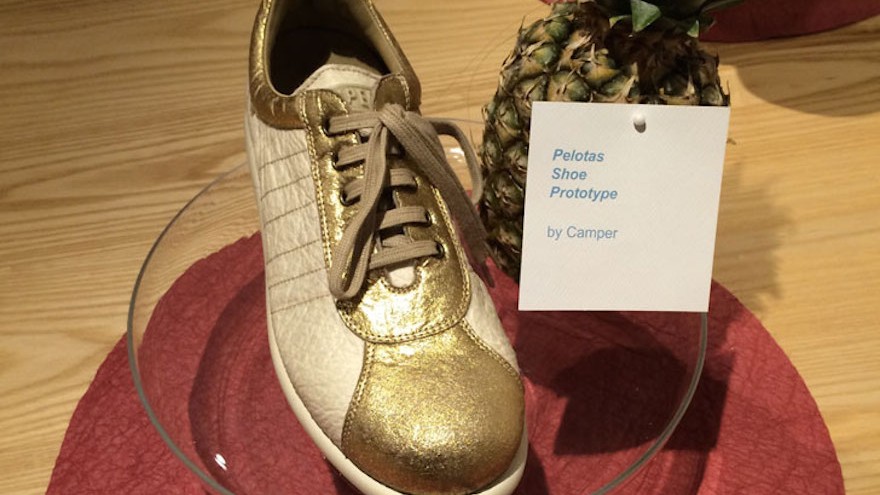

As Piñatex is a by-product of the pineapple harvest, no extra water, fertilisers or pesticides are required to produce Piñatex, which is also biodegradable. It’s available in different thicknesses and finishes such as a blue and cherry-pink faux snake skin or a gold leather finish.

With consumers growing increasingly conscious of the ethics of leather production, there is an opening in the market for alternative materials which, to date, has been taken up by plastics and technical textiles.

While the initial development work leading to Piñatex originated in the Philippines, significant research and development is now being conducted between the UK and Spain. It was the focus of a recent Royal College of Art presentation that showcased sample products by Camper, Puma, and designer Ally Capellino.