Royal College of Art graduate Markus Kayser’s Solar Sinter project explores the potential of desert manufacturing, where energy and materials are available in abundance.

His experiments use sunlight and sand, together with a 3D printing process to combine natural energy and material with high-tech production technology. Kayser’s Solar Sinter asked questions about manufacturing and the possibilities of the full utilisation of the sun, the world’s most efficient source of energy. Here's the story:

In August 2010 Kayser took his first solar machine, the Sun-Cutter, to the Egyptian desert in a suitcase. Here he used this solar-powered, semi-automated low-tech laser cutter, that uses the power of the sun to drive it and directly harnessed its rays through a glass ball lens, to “laser” cut 2D components, using a cam-guided system.

The result was thin plywood components, produced by the Sun-Cutter, with an aesthetic quality that combined machine-made with natural craft.

Kayser’s experiment with the Sun-Cutter led him to utilising the desert’s other major resource – sand, to create glass. The process whereby a powdery substance is converted into a solid form is known as sintering and has become the central process in 3D printing and SLS (selective laser sintering).

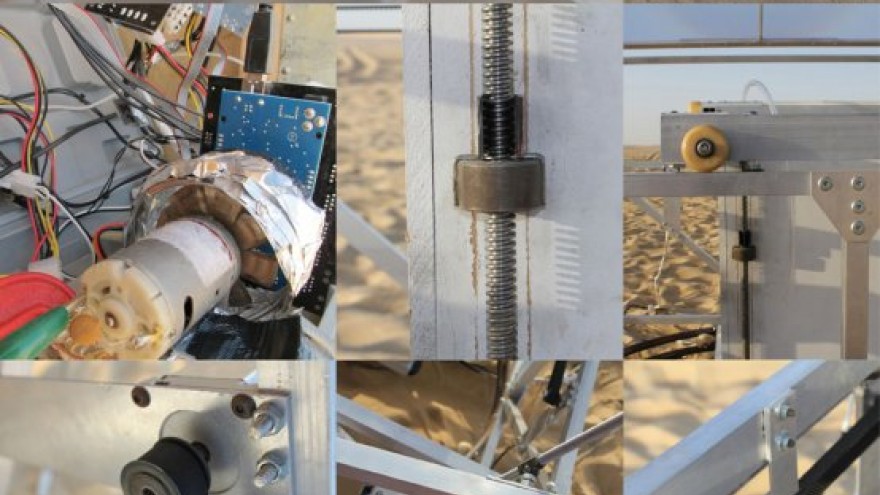

Kayser explains: “These 3D printers use laser technology to create very precise 3D objects from a variety of powdered plastics, resins and metals - the objects being the exact physical counterparts of the computer-drawn 3D designs inputted by the designer. By using the sun’s rays instead of a laser and sand instead of resins, I had the basis of an entirely new solar-powered machine and production process for making glass objects that taps into the abundant supplies of sun and sand to be found in the deserts of the world.”

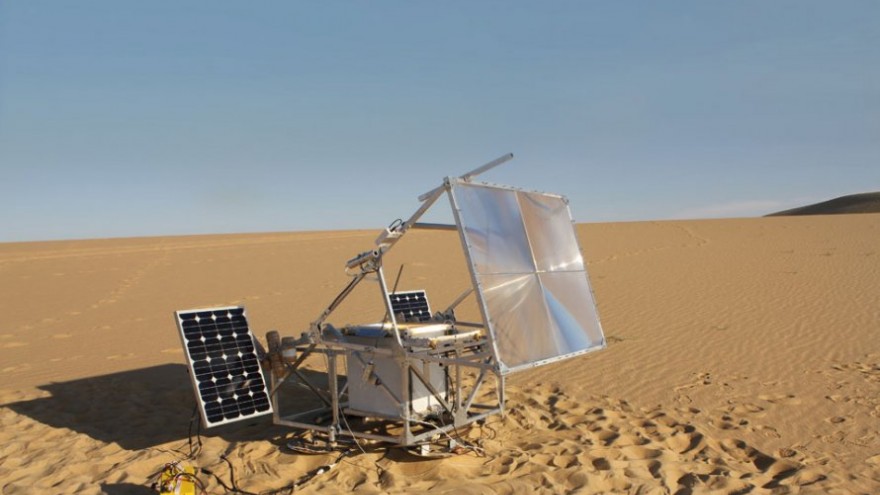

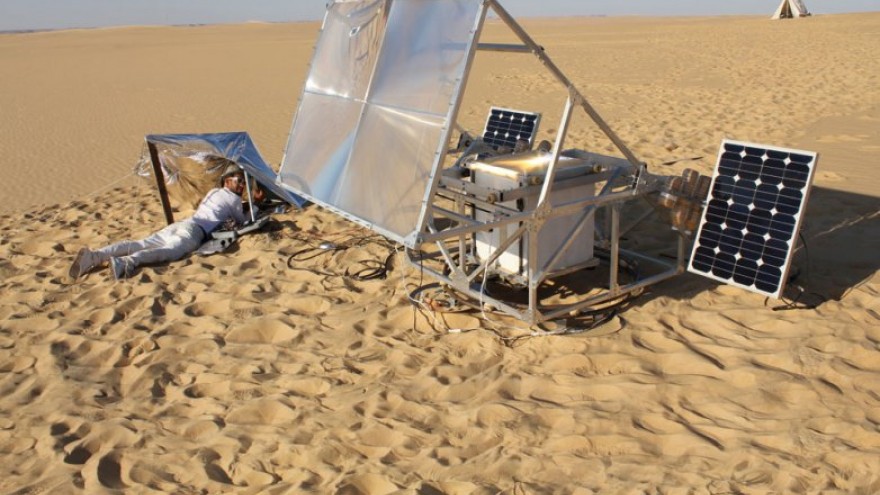

In February 2011 Kayser tested his first manually-operated solar-sintering machine in the Moroccan desert. The results led to the development of the current larger and fully-automated computer driven version - the Solar-Sinter. In May the Solar-Sinter was tested in the Sahara Desert with encouraging results that signal the first steps toward what Kayser envisions as a new solar-powered production tool.