3D-printing technology is behind significant developments in the medical world. At the beginning of 2016, we reported on a group of scientists 3D-printing human tissue for organ regeneration and now, researchers at Johns Hopkins University have found a way to 3D print bones using a material that encourages the growth of natural tissue.

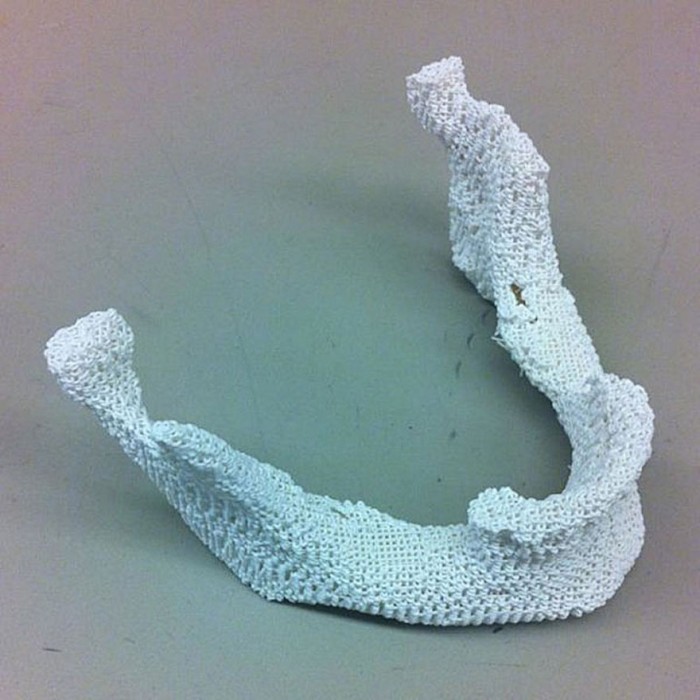

The university team developed the 3D-printed material by combining 30 per cent of pulverised cow bone with a biodegradable polymer (a large molecule made up of a series of identical micro units). The result is a material that can be printed into nearly any bone type or shape, offering a new alternative for surgical procedures involving bone replacement. The implant merges the durability of plastic with the biological coding of natural bone.

The current method of bone replacement requires a surgeon to extract a portion of a patient’s leg bone and sculpt it into the necessary shape before implantation.

The cow bone cells in the new material help the 3D-printed bone attract existing cells in the body, which grow to form natural tissue in and around the implant. In future tests, the researchers plan to replace cow bone with human bone, and they intend to find a way to encourage new blood vessels to penetrate into the framework of the bone implant.