Alaska salmon leather and performance wear made of crab shell fibre are not items commonly found in the wardrobe, but Alaskan start-up Tidal Vision chose clothing manufacture as the next creative way to repurpose and upcycle the two billion pounds of waste generated by the seafood industry in the country.

The company is out to combat the waste issue by purchasing seafood byproducts from sustainable fisheries and using it to create various textiles. The company also hopes to give small seafood businesses a leg up by injecting additional revenue from the sale of their waste products.

Speaking to Sustainable Brands, Tidal Vision’s founder and president, Craig Kasberg said they were forced to go back to the drawing board multiple times to perfect their chitosan fabric – the renewable antibacterial, antimicrobic and antifungal fibre removed from crab shells and spun into fabric.

“Our latest samples are soft and breathable, wick moisture, and naturally completely inhibit bacteria growth – making our apparel fabric odourless. Much like the odourless clothing fabrics that are injected with silver, but our fabric does not release a heavy metal into waterways during washing and wearing out,” he added.

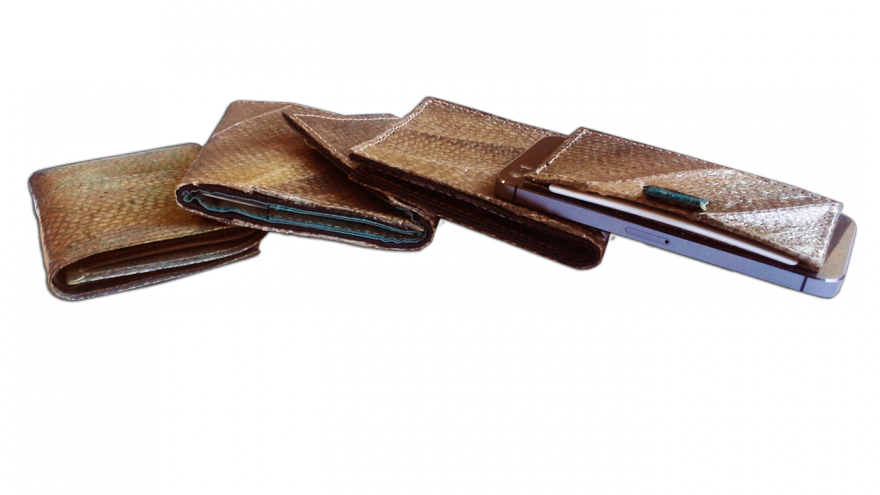

As for the Alaska salmon leather, Kasberg says it smells very similar to vegetable-tanned cow leather since many of the same oils are used in the tanning process. “We are starting by manufacturing accessories such as wallets, bags, and belts. We will also have very limited production runs of handmade Goodyear welt construction shoes and boots available online soon.”