When we discuss carbon emissions or pollution of the atmosphere, it is usually power generation via fossil fuels that is pegged as the culprit. A lesser known contributor to the greenhouse effect is the multi-trillion dollar global industry of construction, specifically the manufacturing of concrete, which accounts for approximately 7 per cent of all greenhouse gas generation.

Now, a cement and concrete technologies company called Solidia Technologies is rolling back this debt to the Earth with hugely efficient means of making basic building blocks. Using the very same raw materials that are used to produce normal concrete such as limestone and clay, Solidia Technologies’s engineers have devised a new approach that is said to reduce the carbon footprint of the construction process by 70 per cent.

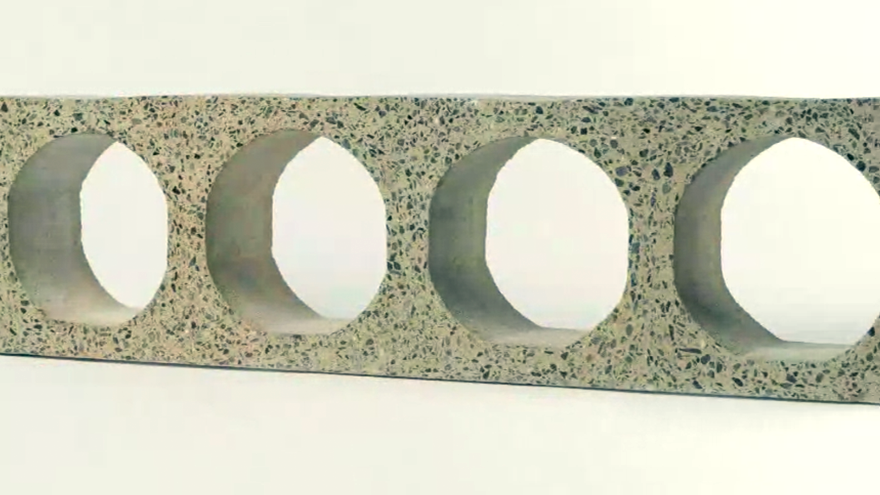

Solidia Technologies’s disruption to normal means of making concrete is not major, but the results are. The ingredients list is practically the same, but a few key differences in the ratios make an impact. Critically, their more sustainable recipe for creating cement includes the use of carbon dioxide as a binding agent instead of water, which is commonly used. Solidia Technologies bricks are also fired at approximately 30 percent less heat in the kiln than is the norm, which saves energy.

According to the engineers, “Easy to adopt anywhere in the world, the technologies produce a sustainable cement and cure concrete with CO2, while utilising manufacturers’ existing infrastructure, raw materials, production methods and specifications.”

The work of companies such as Solidia Technologies enables sustainability to be the driving force even in the design of inanimate objects and architecture around us – and that a reaction to modern dilemmas such as global warming and water shortage can even be found in the cement below our feet.