From the Series

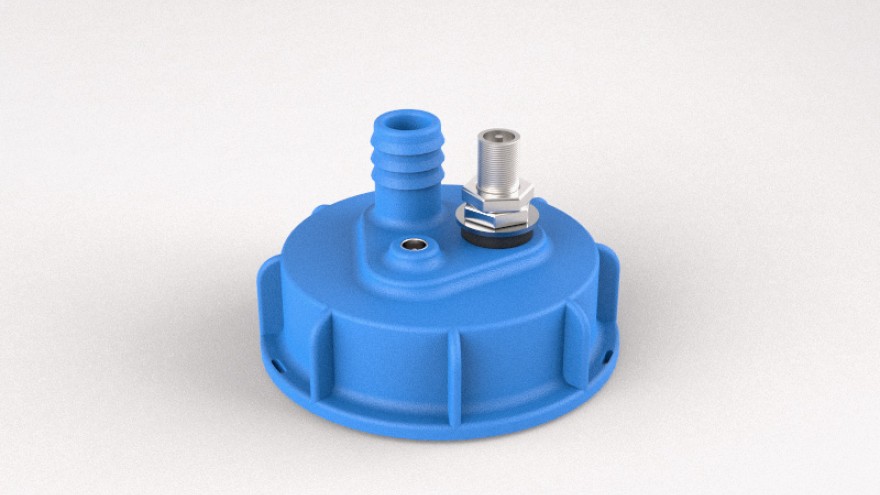

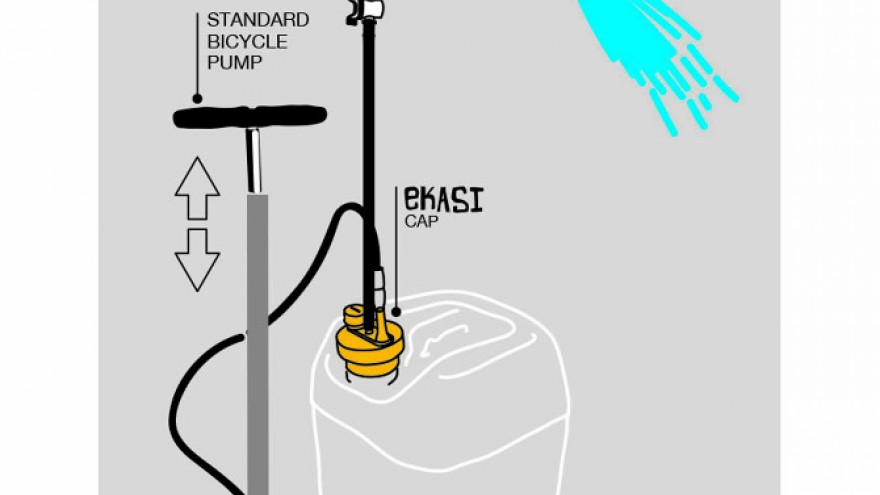

Like the Roadless wheel system and the malaria-combatting Faso Soap, Peter Krige’s Ekasi Water Cap is a good example of a low-cost, needs-based intervention that breaks new ground by working collaboratively with its users in underserved communities. The Water Cap is a specially designed pressure-tight closure that transforms locally available parts - a standard 25-litre water container (commonly used for water collection and storage in unplumbed homes), plastic piping and a bicycle pump - into a portable, pressurised shower unit.

The project started in the final year of Krige’s Innovation Design Engineering degree at the Royal College of Art (RCA). Since graduating last year, the South African native has worked at Bare Conductive, a design and technology studio based in East London, UK. He walks us through his development process.

How did you come up with the idea for the Ekasi Water Cap?

I wanted to apply my design learning to issues close to home and during my initial research at RCA, water usage in the townships spoke to me.

The cap came out of a thinking-through-making process, which followed on from in-depth, human-centered design research and a co-design workshop I held with several township residents, stakeholders and designers involved in this space (ThingKing, Trashback, Heath Nash, Donovan Gillman).

I was so involved in the design process that the idea kind of appeared on its own. There was no “eureka” moment, but a gradual unfolding and shaping through the prototyping process that used the research and conceptual framework as a guide.

Tell us more about how your interest in collaborative designing and "co-visioning" plays out in your work.

During a co-design session like this, the township residents become the experts feeding in all the details and cues necessary for the designers to use their unique skills. It is a magical experience and the intensity of this particular workshop brought out some truly unique insights and ideas.

Having said that, there are moments when these role boundaries blur and you suddenly see the “non-designers” proposing fantastic product ideas and the most appropriate solutions. Or they describe the problem so well that the solution is in the description so to speak.

How did the product evolve during prototyping?

Our professors at the RCA taught us to “fail fast” by testing out our ideas rapidly through physical mockups. I took this advice on board and must have made a dozen versions of the Water Cap. I tried to eliminate anything unnecessary. I wanted to create something that was the bare minimum in material and energy to achieve the desired outcome: a shower experience.

Once I had a design that was robust, I held a user-testing workshop with a family in Khayelitsha. Since this workshop, I have further refined the design based on their feedback and on further manufacturing considerations.

What was the family’s feedback?

The family usually bathed in a steel basin and used plastic jugs to improve the washing experience. This was their first experience in using a shower product!

Initially, when shown the product, it was met with confusion, mostly because it had an unusual form: it didn’t look like a jerry-can cap. This was a major insight from a design perspective and inspired its current form that more obviously references the shape and aesthetic of a standard jerry-can cap.

During the testing of the product some issues occurred in fastening the pipe to the inner and outer nozzles. This has led to a more generous nozzle height and improved barbs to hold the pipe on during operation.

Mostly, the user-testing workshop provided insights for improving communication of the product. Finally, the family requested to purchase one!

I am coming back in Cape Town at the end of June to run a second trial with the Ekasi Water Cap – now with the improved design.

Any plans to get it manufactured and into the marketplace?

In order for a project like this to make an impact, it is important to find the right partners. I am currently working on this and finding ways to fund a more comprehensive trial.

Are you planning other products as part of the Ekasi concept?

For now I am focusing on pushing the Ekasi Water Cap, which is essentially a tool to make something: a shower, a basin, a ... All manner of ad-hoc creativity and material choices can get you to your final design. Township residents are fantastic at this kind of resourceful design thinking and I want to see what they come up with, what they add and where they place it. This, I hope, will inspire the next series of Ekasi products!

You’ve also started to work on a solar thermal system to complement the water cap. Tell us how this works?

The solar thermal system uses a micro-pump inside the solar collector panel that turns on when the sun is out. It then pumps water into the collector where the sun can directly heat it. This is a very simple system and can be made in a basic workshop. The pump and electronic would, however, need to be manufactured by proper industry, where economies of scale could bring the cost down.

Does anything like this system exist yet?

There are other solar thermal collectors out there that use evacuated glass tubes for example, which in my opinion are delicate, expensive and not suitable for an informal settlement environment.