Keilah Bias, an engineering student at Dalhousie University in Nova Scotia, Canada has designed a charcoal presser to assist the villagers of Mikinduri in Kenya with their daily cooking. In Mikinduri, where fuel is hard to come by, villagers hike up the nearest mountain to collect wood and carry it back to their houses.

“As an alternative they make charcoal out of waste – mostly cornstalks and weeds from their farms,” says Bias. “But the current way of doing it is tiresome and ineffective because they use metal pipes as moulds and welded metal as a plunger.”

This process takes long to complete and only yields around two briquettes for cooking. Bias and her teammates set out to develop a product to make the process shorter and more efficient.

“We developed a levered press that compresses charcoal easier and faster. The press only requires one pull of the lever and it makes 16 longer and bigger charcoal briquettes at once,” says Bias.

To make this sustainable charcoal, agricultural waste is packed tightly into a barrel and slow-burned for three hours. The product of this slow burn process is cooled. When it is cool, it is ground into a powder and mixed with water and cooked cassava (or any other starchy root vegetable) to form a paste. The paste is then inserted into the presser.

The hand lever applies five-kilo Newtons of force – the weight of half a car – to compress the agricultural waste into sustainable charcoal.

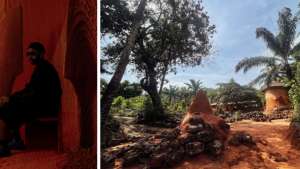

Bias has travelled to Kenya with Mikinduri Children of Hope (MCOH) to test the presser prototype, which received rave reviews. Bias estimated that the presser improved charcoal production by 68 times in terms of energy and time spent in production.

Bias aims to open source the design of the press to allow villagers in Mikinduri and other developing communities to make the press themselves.