Digital fabrication has the power to not only augment contemporary design practice but, within architecture, it also provides room to think about building homes in a faster and more sustainable way.

3D-printed home by architecture students

Danish architecture students, Johanne Holm-Jensen and Mia Behrens, were invited by Space10’s Future Living-lab to conduct a residency project. They were given the task of designing and creating a low-cost 3D-printed home that was not only adaptable but also sustainable.

The home also had be built using sustainable material in order to save money and to help conserve energy.

They built a prototype of a micro-house, made entirely of FSC plywood and a CNC milling machine. The plans for the house are downloadable via open source making it easy for people to customise and make their own designs.

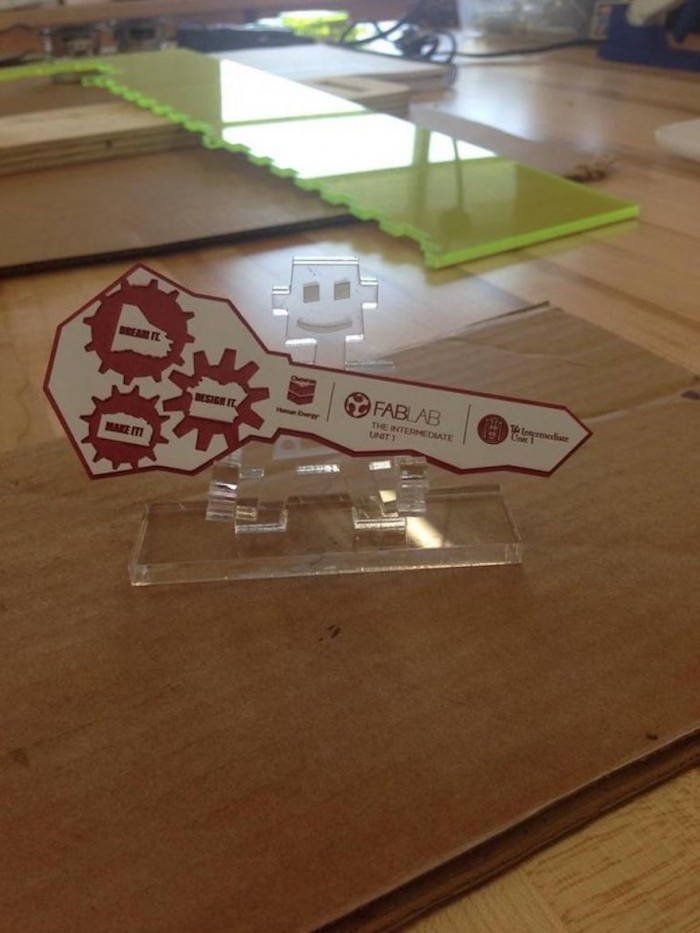

FabLabs

Other programmes such as FabLabs, have created platforms where digital fabrication can become more accessible all over the world.

Fab Lab is the educational outreach component of MIT’s Center for Bits and Atoms (CBA). They provide a platform for people to learn and inmovate with the help of mentors, educators, technologists, researchers and makers.

The network spans 30 countries and 24 time zones.

Originally designed as prototyping platforms for local entrepreneurship, Fab Labs are increasingly being adopted as platforms for project-based, hands-on STEM education.

Apis Cor igloo-style house

Last year, Apis Cor printed an igloo-style house with a bedroom, bathroom, and hallway. They are one of the few companies using a mobile machine on-site rather than creating individual elements off-site and transporting them.

The house is designed to last up to 175 years. This is important, as many houses start to deteriorate because they cannot withstand strong weather conditions or due to not being built properly.

The company hopes to start printing homes worldwide, especially in the developing world. “We want to help people around the world to improve their living conditions. That’s why the construction process needs to become fast, efficient and high-quality as well,” explains Nikita Chen-yun-tai, founder of Apis Cor.

ICON's 3D printed house can be assembled in a day

Another company that is also working within this space is ICON.

They want to answer the simple question: What if you could download and print a home in 24 hours for half the cost? The home was unveiled in March 2018 in Austin, Texas and was built using a prototype of the mobile printer.

They created what is believed to be the first 3D-printed house that is fully up to code and allowed for people to live in.

More on architectural redesign:

Iwo Borkowicz on creating a new model for social housing in Cuba | Design Indaba

Cuba is changing. The next ten to twenty years will shape the futures of the island nation's inhabitants. An aspect of the city that remains fixed though is its housing crisis.